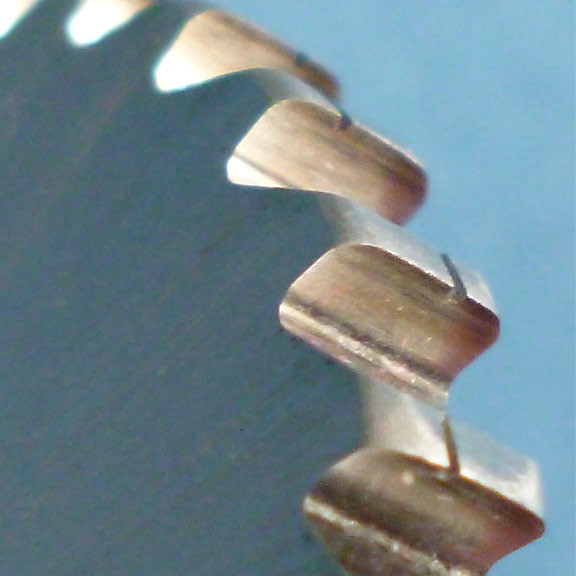

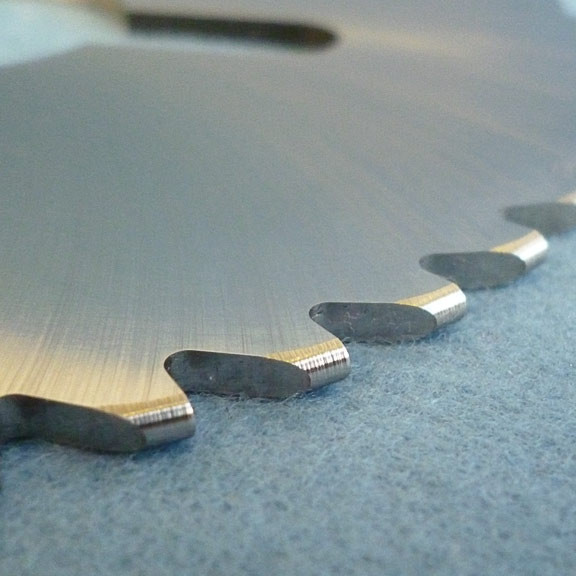

Our company is the exclusive representative of the company Kapmann in SK saw blades for steel. Saw blades are sintered carbides always recommend and adjust according to customer requirements and cutting conditions. We focus on TCT Saw blades for steel, stainless steel, but we also TCT Saw blade for cutting non-ferrous metals and sheet metal. Inserts (SK - cemented carbide, HM - Carbide, TC - tungsten carbide) are produced by sintering technology - sintering tungsten carbide and cobalt (up to 10%, acts as a binder) at high temperature and pressure. Sometimes added as titanium carbide to increase the hardness. The greater percentage of cobalt is, the SK tougher but less wear resistant. Inserts to the tool body soldered by solder consisting of copper and silver.

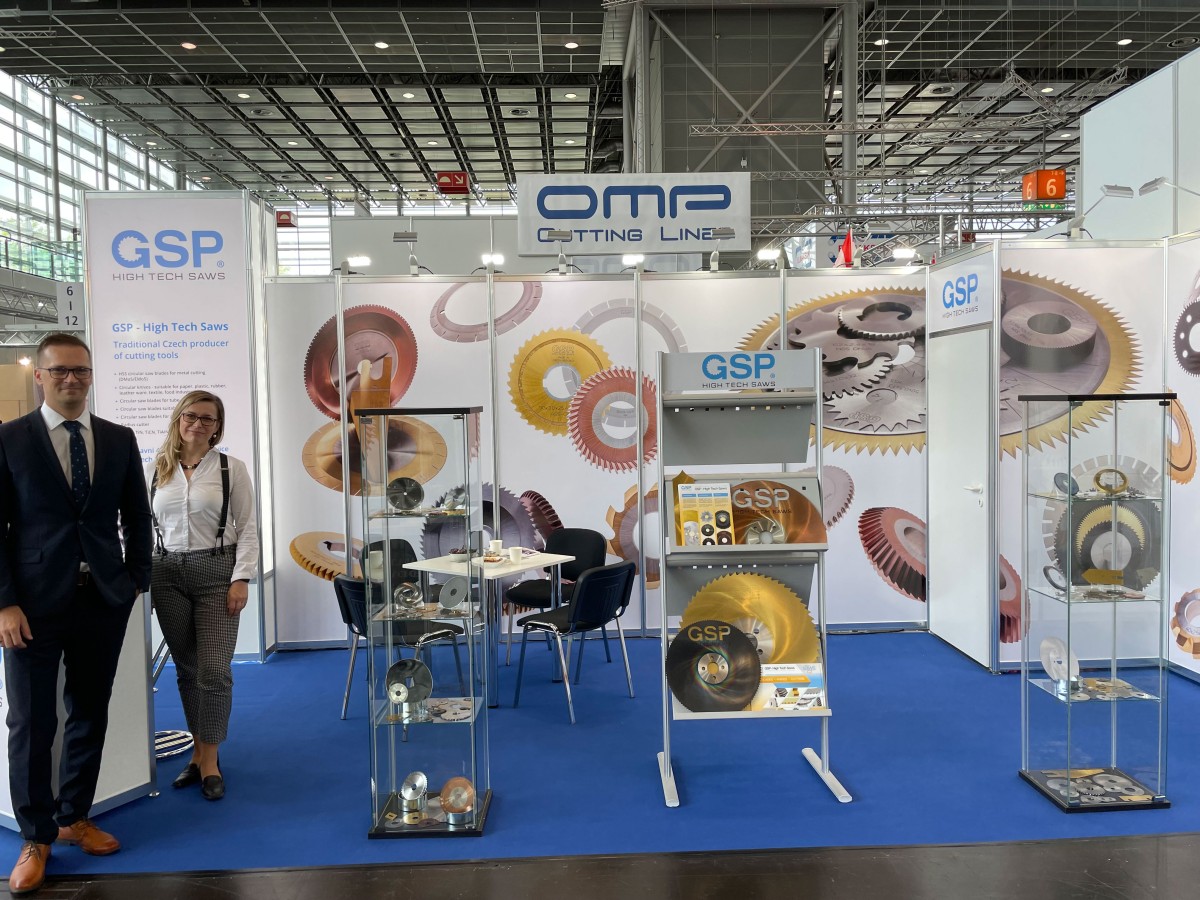

We offer professional tungsten carbide-tipped saw blades and cermet tipped saws for cutting of steel, non-ferrous metals and iron materials.

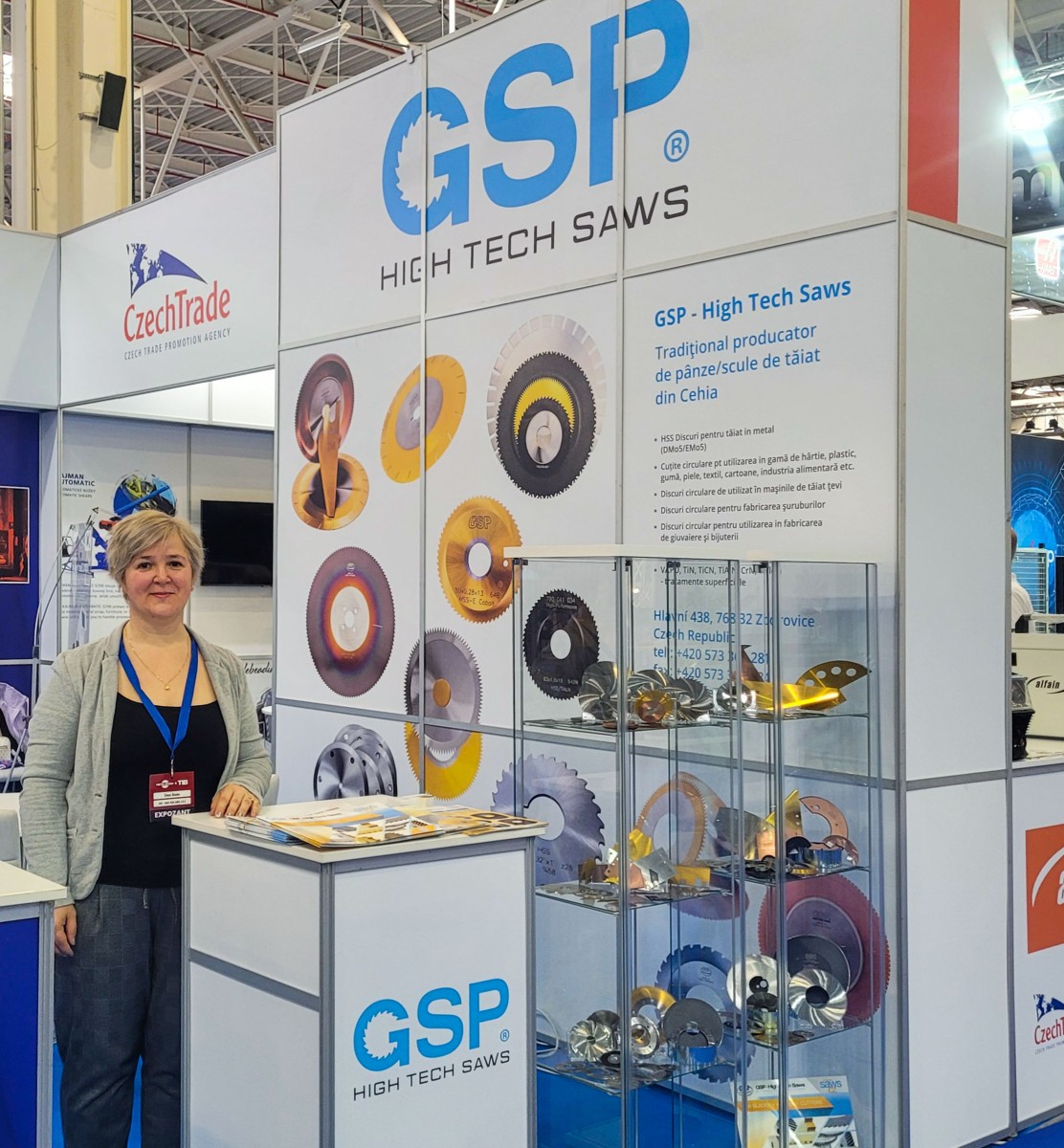

Our assortment of saw blades is designated for the cutting of plastics, construction materials (for example wood-cement board, porous concrete mineral fiber boards and so on). We use only top-quality perfectly hardened steel for the renowned GSP circular saw blades. The blades are created utilizing laser cutting technology and sophisticated research for slots and carbide which provide for a longer-lasting and stronger product.

These are the standard products. There are also customized products, created in close collaboration with the customers systems for specific operational conditions, special tolerances and other requirements.

Coated carbide tipped circular saw blades for steel

Due to the characteristics like, the adapted tooth geometry and the PVD coating, the Starblade offers the perfect economical solution for your sawing process.

Applications:

Cutting steel bars, tubes and profiles together with stainless steel, aluminium and copper alloys.

Range:

from Ø 200 mm to 710 mm.

Advantages:

| T – CUT | TiAIN I | TiAIN DC | TiCN | |

| Micro-hardness HV 0,002 | 3300 | 3200 | 3100 | 3300 |

| Coefficient of friction steel | 0,35 | 0,4 | 0,4 | 0,4 |

| Max. working temp. °C | 900 | 800 | 900 | 400 |

| Colours | blue-black | black-violet | black-gray | copper-gold |

The special designed tooth geometry generates an optimal chip and a minimum of friction during the cutting process. High cutting performances, very short cycle times and the possibility of regrinding the teeth makes this saw blade becomming a very economical tool. The Easycat is also available in coated version.

Applications:

High cutting performance on hard steels up to 1400/mm² ideal for cutting both solids and hollow sections on high powered sawing maschines exellent results on flying saw maschines

Advantages:

| T – CUT | TiAIN I | TiAIN DC | TiCN | |

| Micro-hardness HV 0,002 | 3300 | 3200 | 3100 | 3300 |

| Coefficient of friction steel | 0,35 | 0,4 | 0,4 | 0,4 |

| Max. working temp. °C | 900 | 800 | 900 | 400 |

| Colours | blue-black | black-violet | black-gray | copper-gold |

| Dimension | Teeth number | ||||||||||

| 315 x 2,0 | 40 | 44 | 50 | 54 | 60 | 72 | 80 | 90 | 100 | ||

| 315 x 2,4 | 40 | 44 | 50 | 54 | 60 | 72 | 80 | 90 | 100 | ||

| 350 x 2,6 | 40 | 44 | 50 | 54 | 60 | 72 | 80 | 90 | 100 | 120 | 128 |

| 350 x 2,9 | 40 | 44 | 50 | 54 | 60 | 72 | 80 | 90 | 100 | 120 | 128 |

Carbide tipped saw blade for steel

The particularity of Multicat consists in its specific design which is adapted to the requirements of the customer and the surrounding conditions of the sawing process. Therefore there are numerous different tooth geometries besides several versions.

Applications:

Cutting steel bars, tubes and profiles together with stainless steel and copper alloys.

Range:

Ø 200 mm to 2000 mm.

Advantages:

Dear customer, you have the opportunity to make a preliminary request for this product. In the inquiry basket you can specify your product requirements according to the table, or you can enter any questions for the sales representative. The sales representative will contact you as soon as possible.