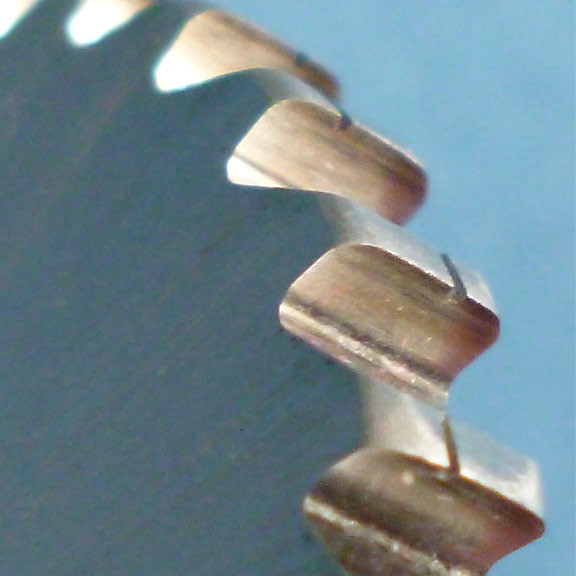

Usage:

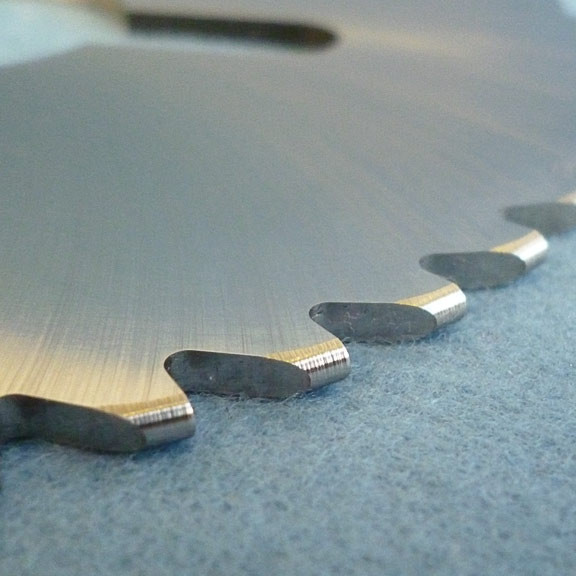

Characteristics:

SK saws for cutting light metals and plastics - 22 5387 - 11 TFZ N |

||||

|

Diameter

(mm) |

Thickness

(mm) |

Body thickness

(mm) |

Bore diameter

(mm) |

Teeth number |

| 160 | 2,8 | 2,2 | 20 | 48 |

| 190 | 2,8 | 2,2 | 30 | 56 |

| 200 | 3,2 | 2,5 | 30 | 60 |

| 250 | 3,2 | 2,5 | 30 | 80 |

| 300 | 3,2 | 2,5 | 30 | 96 |

| 300 | 3,2 | 2,5 | 40 | 96 |

| 350 | 3,6 | 2,8 | 30 | 108 |

| 350 | 3,6 | 2,8 | 40 | 108 |

| 400 | 3,6 | 2,8 | 30 | 120 |

SK saws for cutting light metals and plastics - 22 5387 - 11 TFZ P |

||||

|

Diameter

(mm) |

Thickness

(mm) |

Body thickness

(mm) |

Bore diameter

(mm) |

Teeth number |

| 250 | 3,2 | 2,5 | 30 | 80 |

| 300 | 3,2 | 2,5 | 30 | 96 |

| 350 | 3,6 | 2,8 | 30 | 108 |

SK saws for cutting light metals and plastics - 22 5387 - 13 TFZ N |

||||

|

Diameter

(mm) |

Thickness

(mm) |

Body thickness

(mm) |

Bore diameter

(mm) |

Teeth number |

| 250 | 3,2 | 2,5 | 30 | 60 |

| 300 | 3,2 | 2,5 | 30 | 72 |

| 350 | 3,6 | 2,8 | 30 | 84 |

| 350 | 3,6 | 2,8 | 40 | 84 |

| 400 | 3,6 | 2,8 | 30 | 96 |

| 420 | 4,0 | 3,2 | 30 | 96 |

| 450 | 4,0 | 3,2 | 30 | 108 |

| 500 | 4,0 | 3,2 | 30 | 120 |

SK saws for cutting light metals and plastics - 22 5387 - 13 TFZ P |

||||

|

Diameter

(mm) |

Thickness

(mm) |

Body thickness

(mm) |

Bore diameter

(mm) |

Teeth number |

| 200 | 3,2 | 2,5 | 30 | 48 |

| 250 | 3,2 | 2,5 | 30 | 60 |

| 300 | 3,2 | 2,5 | 30 | 72 |

| 350 | 3,6 | 2,8 | 30 | 84 |

| 350 | 3,6 | 2,8 | 40 | 84 |

| 400 | 3,6 | 2,8 | 30 | 96 |

| 400 | 3,6 | 2,8 | 40 | 96 |

| 450 | 4,0 | 3,2 | 30 | 108 |

| 450 | 4,0 | 3,2 | 40 | 108 |

| 500 | 4,0 | 3,2 | 30 | 120 |

Dear customer, you have the opportunity to make a preliminary request for this product. In the inquiry basket you can specify your product requirements according to the table, or you can enter any questions for the sales representative. The sales representative will contact you as soon as possible.